Hot-wire and Hot-film Probes

Hot-wire and Hot-film Probes

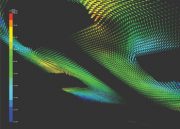

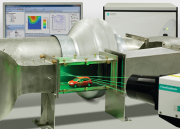

Dantec Dynamics offers a complete probe system for use with Constant Temperature Anemometers (CTA). The CTA anemometer is today’s most widely used instrument for measurement and analysis of the micro-structures in turbulent gas and liquid flows.

The CTA probe program comprises a variety of probe types and probe configurations. There is a probe for almost any measurement situation.

Infos / Datasheet

General introduction to probe programme

The main probe features are:

- Fast response. Fluctuations up to 100 kHz or more can be measured.

- High dynamic range. Velocities from a few cm/s up to several hundred m/s can be measured with almost constant sensitivity.

- Little disturbance of the flow, due to small sensor sizes.

- High spatial resolution. Eddies down to some tenths of a mm can be resolved.

- Continuous signal.

The basic working principle makes it possible to determine fluctuations in any parameter that, in addition to the velocity, influences the heat transfer from the sensor -i. e. density, pressure, temperature and composition- provided proper means are taken.

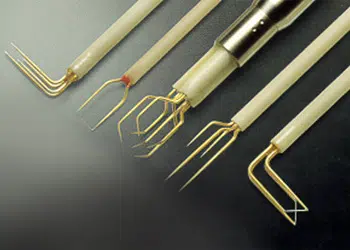

Probe construction

In general, a probe consists of the following:

- Sensor, forming the heating element.

- Sensor supports, carrying the sensor and leading current to it.

- Probe body, carrying the sensor supports.

- Connector, providing electrical connection to the probe support or probe cable.

Probes may have one, two or three sensors for use in one-, two- or three-dimensional flows, respectively. Each sensor requires its own anemometer bridge.

The sensor may either be a thin wire suspended between two prongs or a thin metal film deposited on an electrically insulating substrate. Film sensors can be cylindrical (fiber-film probes) or non-cylindrical (film probes). Wire sensors are used in gases and in non-conducting liquids, where as film sensors are primarily designed for use in water and other conducting liquids.

The sensor materials are selected to provide maximum flow sensitivity and highest possible mechanical strength with a minimum of thermal inertia. The size of the sensor and its mounting are selected to give minimal disturbance of the flow.

Probe body design

The probe bodies are designed to provide a rigid, aerodynamic mounting of the sensors and sensor supports with a reliable electrical contact further on to the probe support or to the probe cable.

Probe supports

All plug-in probes are mounted using probe supports. They serve as the electrical connection between probe and probe cable and provide a mechanical mount for the probe at the same time.

Manufacturer’s responsibility

Dantec Dynamics is responsible for the safety, reliability and performance of the items described in this catalog only if:

- The specific environmental conditions correspond to the requirements stated for the specific item in this catalog or on the probe or probe support container.

- Persons authorized by Dantec Dynamics carry out modifications or repairs.

- The items are used in accordance with the recommendations given herein or on the probe or probe support container.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)