We can provide following service and support for you

Here is an overview of our service and support activities. If you have any questions, feel free to contact us.

Zertifizierungswartung

Maintenance and inspection of the system by a technician of the company Ing. Prager Elektronik HandelsGmbH with issuance of a certificate.

Maintenance includes cleaning the system, replacing parts from a maintenance kit (if recommended by the manufacturer), and a functional test.

The review includes validation using NIST certified standards and issuing a test certificate. All necessary standards are included in the price.

An included, one-year maintenance contract assures you preferential assistance with application questions and shorter reaction times in case of a defect. Optionally, even faster reaction times or the loan of a replacement device (if available, if a repair cannot be performed on site) can be arranged.

Additional required service activities, installations, configuration settings and replacement parts are not included and must be invoiced separately.

Vorzugswartung

Maintenance and inspection of the system by a technician of the company Ing. Prager Elektronik HandelsGmbH with issuance of a certificate. Plus free visit in case of failure.

Maintenance includes cleaning the system, replacing parts from a maintenance kit (if recommended by the manufacturer), and a functional test.

The review includes validation using NIST certified standards and issuing a test certificate. All necessary standards are included in the price.

An included, one-year maintenance contract assures you preferential assistance with application questions and shorter reaction times in case of a defect. Then, the first service visit is free of charge (you only pay for the material) and you will receive a 20% discount on all other required visits within the maintenance period, but not on the replacement parts. Optionally, even faster reaction times or the loan of a replacement device (if available, if a repair cannot be performed on site) can be arranged.

Additional required service activities, installations, configuration settings and replacement parts are not included and must be invoiced separately.

Garantiewartung

Maintenance and inspection of the system by a technician of the company Ing. Prager Elektronik HandelsGmbH with issuance of a certificate. Plus one year free repairs.

Maintenance includes cleaning the system, replacing parts from a maintenance kit (if recommended by the manufacturer), and a functional test.

The review includes validation using NIST certified standards and issuing a test certificate. All necessary standards are included in the price.

An included, one-year maintenance contract assures you preferential assistance with application questions and shorter reaction times in case of a defect. In doing so, the company Ing. Prager Elektronik HandelsGmbH assumes all necessary tasks and material costs for repairs that were not caused by normal wear and tear or third-party debt (warranty extension). Optionally, even faster reaction times or the loan of a replacement device (if available, if a repair cannot be performed on site) can be arranged.

Additional required service activities, installations, configuration settings and consumables are not included and must be billed separately.

The general terms and conditions of the company Ing. Prager Elektronik HandelsGmbH apply to all maintenance contracts.

GMP - Pharma - IQ/OQ

We offer FDA and MCA compliant checks (IQ / OQ) for nearly all our devices – with certified standards, certified meters, trained technicians and appropriate documentation.

We are happy to create a suitable offer for you!

The general terms and conditions of the company Ing. Prager Elektronik HandelsGmbH apply to all maintenance contracts.

Particle Measurement / Particle Characterization

Malvern Panalytical Mastersizer 3000+

- Particle size measurement – laser diffraction

- Measurement range: 0.01µm – 3500µm Diameter

- Wet and dry measurements

- sample information sheet Particle Size

Malvern Panalytical Zetasizer

- Particle size measurement – dynamic light scattering

- Measurement range 0.3nm – 10µm Diameter

- sample information sheet Particle Size submicron

- Zetapotential measurements

- Measurement range 0.3nm – 100µm Diameter

- sample information sheet Zetapotential

Malvern Panalytical Morphologi G3

- Particle shape measurement

- Dry and wet measurements

- Measurement range 0.5µm – 10mm

- Filter measurements

- Magnifications: 2.5X, 5X, 10X, 20X, 50X

- sample information sheet Particle

- sample information sheet Particle filter

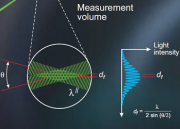

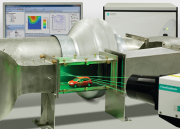

Malvern Spraytec

- Particle size measurement – laser diffraction

- contactless for Sprays and nozzles

- measurement range: 0.1 – 2000µm

Rheosense Viscometer

- viscosity measurements

- high shear rate

- smallest sample volume: 20µl

Latex Standards

Latex Standard particles are available as size standards between 20nm and 2000µm. The Particles are available as a dry powder and suspended in liquid. Some liquid standards are also available as coloured particles.

We also can provide you couting standards with a known amount/ml.

The standards paticles are tracable to NIST or USP<778>.

Zetapotential Standard

The zetapotential standard is a transfer standard with a known value of -42mV +/-4.2 mV. It contians latex beads and is already mixed and packed in syringes of 10ml. One package contains 10 syringes which can be used in the Zetasizer Systems to check the instrument or to use it for your application.

QAS Standards

Quality Audit Standards (QAS) can be used to check the performance of your Malvern Instrument by yourself.

- QAS Standards are size standards with a broad size distribution and available for the Mastersizer 2000, Mastersizer 3000, and Mastersizer Mikro/ Mikorplus. For the Morphologie G3 is a certified Glasslide available and for its dispersing unit we can offer a QAS Standard as well.

- QAS Standards are packed in “one-shot” amount in a small plastic bottle to provide you a very easy handling and quick handling.

Seeding Material

The choice of the right seeding material to scatter the light from laser beams or a light sheet can be crucial to the acquisition of successful experimental data. Numerous properties of the particle material have to be taken into consideration when selecting the appropriate seeding medium for a particular measurement task. Mean particle size is only one of the parameters. Others include specific gravity, particle shape, width of size distribution, surface characteristics and refractive index.

To satisfy seeding requirements for different flow applications a range of seeding materials and equipment are available from Prager Elektronik.

Polyamide seeding particles (PSP)

These are produced by polymerisation processes and therefore have a round but not exactly spherical shape. They are microporous and strongly recommended for water flow applications.

- Size (µm): 5, 20, 50

- Size distribution: 1 – 10 µm, 5 – 35 µm, 30 – 70 µm

- Particle shape: round

- Density: 1.03

- Meltingpoint: 175

- Refractive Ind.: 1.5

Hollow glass spheres (HGS)

Intended primarily for liquid flow applications, these are borosilicate glass particles with a spherical shape and a smooth surface.

- Size (µm): 10

- Size distribution: 2 – 20µm

- Particle shape: spherical

- Density: 1.1

- Meltingpoint: 740

- Refractive Ind.: 1.52

Silver-coated hollow glass spheres (S-HGS)

Intended primarily for liquid flow applications, these are borosilicate glass particles with a spherical shape and a smooth surface. A thin silver coating further increases reflectivity.

- Size (µm): 10

- Size distribution: 2 – 20µm

- Particle shape: spherical

- Density: 1.1

- Meltingpoint: 740

- Refractive Ind.: 1.52

Fluorescent polymer particles (FPP)

These particles are based on melamine resin. Fluorescent dye (Rhodamine B:) is homogeneously distributed over the entire particle volume. In applications with a high background light level, fluorescent seeding particles can significantly improve the quality of vector maps from PIV and LDA measurements.

- Size (µm): 10, 30, 75

- Size distribution: 1 – 20 µm, 20 – 40 µm, 50 – 100 µm

- Particle shape: spherical

- Density: 1.5

- Meltingpoint: 250

- Refractive Ind.: 1.68

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Facebook. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)