SOPAT

SOPAT

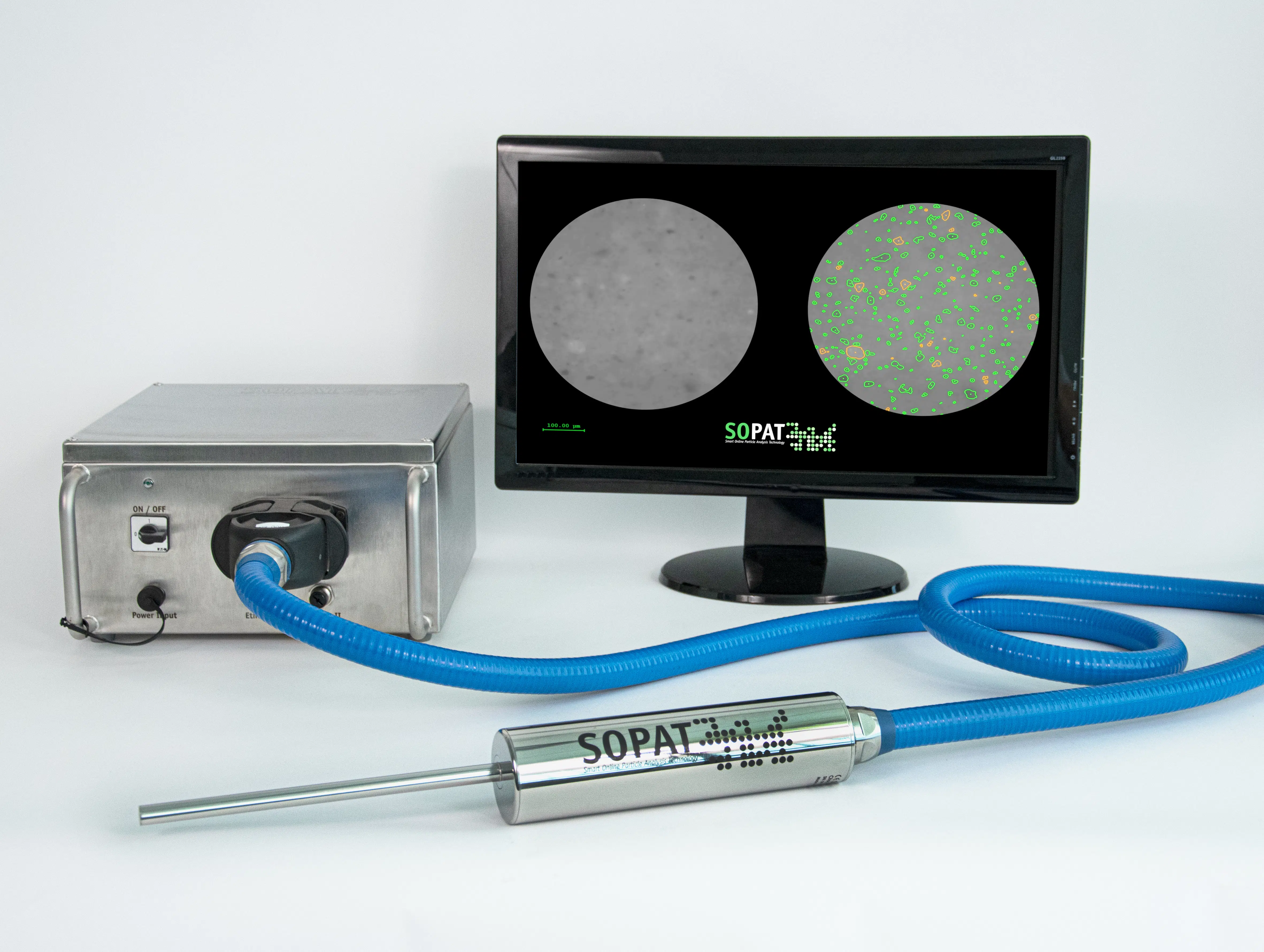

In almost all cases the quality of a product is dependent of the characteristics of the available particles and their size distribution. SOPAT offers a flexible particle measurement system. It consists of a tailor made SOPAT probe, the innovative SOPAT software, and the SOPAT central box, all of which can be customized to your needs.

The outer tube that comes into contact with the medium is variably adjustable in terms of length, as well as temperature and pressure durability.

This allows the fabrication of a SOPAT particle measurement system optimally tuned to your production process.

A multitude of various probes are available in order to reliably and automatically gather the desired particle size range. With SOPAT technology, you are always one step ahead of the competition!

Infos / Datasheet

Sie sehen gerade einen Platzhalterinhalt von Youtube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Youtube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Youtube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSOPAT has systems with:

- robust materials that fulfill the criteria for SIP (sterilization in place) and CIP (cleaning in place)

- flat, smooth surfaces that guarantee efficient sterilization

- a shape without edges or corners that enables simple cleaning and prevents the retention of gases or other mediums

- a casing suited to specialized, challenging production conditions (such as high pressure, high temperature, or aggressive and abrasive mediums)

We offer a wide portfolio of probes for your application. It is possible to measure particle sizes between 0.5 and 10,000 µm insitu with SOPAT probes, even under the most intense conditions.

The SOPAT macroscope probe, InView, allows the observation of processes through a window for particle sizes between 10 and 50,000 µm.

In addition to accurate measurement tools, highly developed software is also necessary to correctly collect data and comprehensively prepare it. The SOPAT software is the key ingredient of your new SOPAT particle measurement system. With the integrated ProbeControl, you have a high performance tool to generate live pictures of your production process that can be archived if desired.

The unique architecture of the picture analysis algorithm allows a flexible and automated evaluation of the gathered pictures. A connection to your Process Control system with the SOPAT monitor is ideal. With workflow cutomizationit automates all necessary steps from collection of pictures to the representation of the results of the analysis.

The central box is the interface between the probe and the evaluation computer for the particle analysis. It fulfills all of the demands of protection category IP65 (complete electric shock protection, dust protection, water protection from all directions).

The maximum distance between the central box and the computer can be 70 meters, otherwise a repeater is required to increase the signal strength. The central box contains the stroboscope, which acts as a light source for the stick probes. For especially challenging conditions, the central box can also be contained with nitrogen or oxygen overpressure, aka the ATEX varient.

- Cooling tube

- Tripod

- Transmission Lighting

- Reflection Module

- Process Connectors

- Micro-flow cell

- Calibration Standards

In case of explosion hazards, our SOPAT particle measurement system is available in an ATEX variant that can preform particle size measurements under the hardest conditions. The successful ATEX certification in accordance to Appendix VII of the 2014/34/EU regulation enables the deployment under explosion hazards.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenSie sehen gerade einen Platzhalterinhalt von Facebook. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)