TMA 402 F1 or F3 Hyperion®

TMA 402 F1 und F3 Hyperion®

Thermomechanical analyzer – vertical Dilatometer

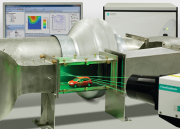

The heart of the TMA 402 Hyperion® is a highly precise inductive displacement transducer (LVDT).

This technology has stood the test of time; it is also used for dilatometers and allows measurement of even the smallest of length changes, into the nanometer range (digital resolution of 0.125 nm).

Simultaneous measurement of force and displacement signal

The force operating on the sample is generated electromagnetically in the TMA 402 Hyperion®. This guarantees a quick response time for experiments with a changing load, e.g. tests on creep behaviour. A highly sensitive force sensor (digital resolution < 0.01 mN) continuously measures the force exerted via the push rod and readjusts it automatically. This sets the TMA 402 Hyperion® apart from other instruments, which use only preset values.

Functional principle:

Thermomechanical Analysis (TMA) is a technique for determining the dimensional changes in solids, liquids or pasty materials as a function of temperature and/or time under a defined mechanical force (DIN 51005, ASTM E 831, ASTM D696, ASTM D3386, ISO 11359 – Parts 1 to 3). It is closely related to dilatometry, which determines the length change of samples under negligible load (DIN 51045).

TMA 402 F1 and F3 Hyperion® supports with:

- Linear thermal expansion

- Coefficient of thermal expansion

- Phase transition temperatures

- Sintering temperatures

- Shrinkage steps

- Glass transition temperatures

- Dilatometric softening points

- Volumetric expansion

- Density changes

- Delamination

- Decomposition temperature

- Sintering kinetics

- Creep

- Relaxation

- Stress/strain curve

Advantages of the TMA 402 F1 and F3 Hyperion®:

- Modular Concept with interchangeable furnaces (compatible with other NETZSCH instruments) for easy and cost-effective expansion and retrofitting

- Gas flows with up to 4 MFCs, controllable via software with programmable atmosphere change for the analysis of e.g. oxidation behaviour without manual valve operation

- Digitally programmable force or displacement control up to 4 N (only for F1, 3 N for F3 ) with linear or stepwise force alteration and continuous force modulation for determining visco-elastic properties like relaxation, creep and stress/strain

- Various accessories for an expanded application range, e.g., for measuring powders, liquids, pastes or metals

- Proteus®-Software (including device license)

For further information, please refer to the technical data sheet or the brochure.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)