DSC 404 F1 Pegasus®

DSC 404 F1 Pegasus®

The DSC 404 F1 Pegasus®, High-Temperature Differential Scanning Calorimeter, is designed for the exact determination of specific heat of high-performance materials at high temperatures.

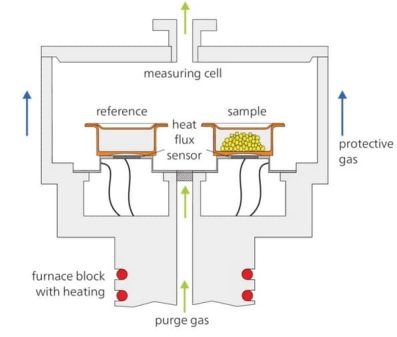

Functional principle:

A DSC measuring cell consists of a furnace and an integrated sensor with designated positions for the sample and reference pans. The sensor areas are connected to thermocouples or may even be part of the thermocouple. This allows for recording both the temperature difference between the sample and reference side (DSC signal) and the absolute temperature of the sample or reference side.

DIN 51007 and ISO 11357-1 recommend the portrayal of endothermic processes with upward ordinate amplitude. In, for example, ASTM E793 and E794, downward application of the endothermic direction is suggested. This is why the NETZSCH Proteus® software allows for the direction of application for endothermic and exothermic processes to be selected.

DSC 404 F1 Pegasus® supports with:

- Determination of thermodynamic properties of ceramics and metallic high-performance materials

- Performance of quantitative enthalpy and cp determinations in a pure gas atmosphere

- Vacuum-tight up to 10-4 mbar for creation of highly pure atmospheres for tests on materials sensitive to oxidation

- Characterization of amorphous metals, shape memory alloys and inorganic glasses

Advantages of the DSC 404 F1 Pegasus®:

- Up to eight interchangeable furnace types are available

- Maximum temperature range from -150 to 2000 °C

- Maximum heating rate of up to 50 K/min

- ASC of up to 20 samples and reference crucibles (optional)

- Gas atmospheres: inert, oxidizing, reducing, vacuum

- Coupling options with FTIR, MS, FTIR-MS, GC-MS or GC-MS-FTIR

- Proteus® software (including device license)

For further information, please refer to the technical data sheet or the brochure.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)