Mastersizer 3000

Mastersizer 3000

The Mastersizer 3000 laser diffraction particle size analyzer delivers rapid, accurate particle size distributions for both wet and dry dispersions with the minimum of effort. Measuring over the nanometer to millimeter particle size ranges, it packs exceptional performance into the smallest of footprints, bringing operator-independent measurements that every user can rely on.

Infos / Datasheet

Sie sehen gerade einen Platzhalterinhalt von Youtube. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr InformationenThe Mastersizer 3000 is the latest generation of the world’s most popular particle sizing instrument. Incorporating expert engineering and applications know-how into every stage of its design, it delivers:

- Class-leading particle sizing performance in a compact footprint.

- Intuitive software with built-in expertise to ease your workload.

- Flexible reporting to display your data the way you want it.

- Rapid and effective wet dispersion.

- Fast, reliable particle size measurement of fragile and cohesive dry powders.

- Mastersizer know-how throughout, for results you can rely on.

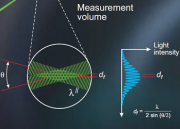

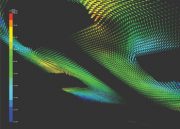

The Mastersizer 3000 uses the technique of laser diffraction to measure the size of particles. It does this by measuring the intensity of light scattered as a laser beam passes through a dispersed particulate sample. This data is then analyzed to calculate the size of the particles that created the scattering pattern.

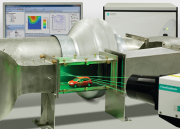

A typical system is made up of three main elements:

- Optical bench – A dispersed sample passes though the measurement area of the optical bench, where a laser beam illuminates the particles. A series of detectors then accurately measure the intensity of light scattered by the particles within the sample for both red and blue light wavelengths and over a wide range of angles.

- Sample dispersion units (accessories). Sample dispersion is controlled by a range of wet and dry dispersion units. These ensure the particles are delivered to the measurement area of the optical bench at the correct concentration and in a suitable, stable state of dispersion.

- Instrument software. The Mastersizer 3000 software controls the system during the measurement process and analyzes the scattering data to calculate a particle size distribution. It also provides both instant feedback during method development and expert advice on the quality of the results.

Picture

Model

Sample volume

Comment

Hydro EV

Wet dispersion unit for flexible sample volume

exchangeable sample volume with beakers

250ml/600ml/1000ml

Easy sample recovery

Hydro SM

Wet dispersion unit for small sample volume

50ml to 120ml

Ideal for samples in non-aqueous dispersants with minimum solvent consumption.

Hydro Insight

Camera to see your dispersion

depending on the dispersion unit

morphology data of your sample

It’s possible to operate the dispersion-units with differently liquids how for example: water, alcohols or solvents. There is also the possibility to use more dispersion-units on one Mastersizer 3000.

Picture

Model

Sample volume

Comment

Setting new standards for dry powder dispersion, the Aero S has been designed from the ground up based upon fundamental powder dispersion theory. The modular design ensures rapid and reproducible dispersion of the widest range of samples from cohesive powders to fragile materials.

Precise control of the sample feed rate and the applied dispersion pressure ensure the Aero system delivers the most reproducible results possible.

Sie sehen gerade einen Platzhalterinhalt von Google Maps. Um auf den eigentlichen Inhalt zuzugreifen, klicken Sie auf die Schaltfläche unten. Bitte beachten Sie, dass dabei Daten an Drittanbieter weitergegeben werden.

Mehr Informationen

![[:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:] [:de]kategorie_stroemung_staudruck[:en]kategorie_stroemung_staudruck2[:]](https://www.prager-elektronik.at/wp-content/uploads/2018/01/kategorie_stroemung_staudruck2-180x129.png)